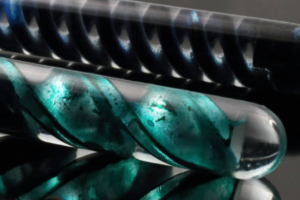

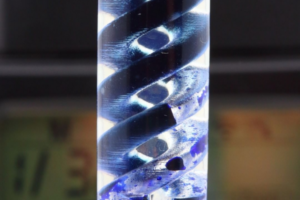

The World’s First Purpose built 3D printed fountain pens are being built, literally adding layer on layer even as you read this. Manufacturing through such “adding”, instead of removing material, opens up endless possibilities for design – unique design, to be precise. Additive manufacturing revolution is not about making things at home, it is about making things that used to be impossible.

I caught up with the dreamers behind the epoch making project – Andrzej and Jerry, who speak their hearts out in an one to one Exclusive. Read on:

A 3D Fountain pen? How on Earth did you hit on that idea? Why?

AT: My original plan was to make a fountain pen with a unique filling mechanism. I made the design and ordered some 3D printed parts to create a prototype. Things did not go exactly as planned and there were many issues with the pen; it was far from working. While I was working on the second revision I decided to design some weirdly looking pen barrels, just because additive manufacturing has almost no limitations on shape. As it turned out, this was much more fun than my original project and the rest is history.

What will make your creation special? At which segment of the market – considering the unique, if I may say, even quirky nature of fountain pen collectors, are you trying to place your offering?

AT: Our designs have one common factor in mind – they are not 3D printed just for the sake of 3D printing. It is essentially impossible to create them using other, more traditional methods. It is not about utilizing the latest technologies, although the buzz-words do help get traction, but about design that was not seen before. We are targeting fountain pen collectors, as we are fully aware that our creation is not really a good replacement for a trusty Lamy 2000 in hands of a college / school student. We are making a beautiful object first, and a fountain pen second.

What are you doing to market your product? Especially in view of the fact that it is an extremely sensitive niche of collectors that you are aiming to win over – people who are flooded with a plethora of products from well entrenched pen makers.

JT: Personally, I feel that our product is so different from the other offerings, that its very appearance is what attracts the pen people. Although there’s many pens out there, most are similar to the majority in both design and function. The crazier we make it, I think more people would like it and that’s what we’d aim for.

AT: While we are targeting a niche within a niche, we are aiming at the whole world, which is a big place. This is a truly international product: designed by a polish guy living in Norway, first units were printed by a Portuguese couple in Belgium, the project transformed from a one-time hobby into a company in hands of a Chinese-Canadian, utilising German nibs and American resins.

What are the prospects of the initial novelty value wearing off? What are your plans for the future?

JT: The novelty should wear out only when most people have seen, used or at least tried one of our pens. And with that kind of awareness and distribution, personally, I’d be a very happy kid. Lots of new products and ideas in the works, stay tuned!

AT: We have way more ideas than time to work on them! We are planning to continue providing products in form and function never seen before.

![]()

What advice do you have for serious hobbyists like you who want to take the plunge and convert their passion to profession?

AT: Just try. Try different things and see what sticks. You never know where you will find your new passion.

JT: When people ask to buy the stuff you make, that’s a good indicator that you’re doing something right. People’s preferences and tastes change, so be prepared to change your products as well. I wouldn’t be qualified to speak on a conversion to full time work though, since I’ve never held a full time position haha.

Anything that you would want to communicate to our readers?

AT: This is the very first official interview with Additive Collaboration Projects, the home of Additive Pens. We are honored to be here!

JT: We’ve worked with Aditya at The Pen World in the past, and we’re hoping to bring more of our pens to India soon!

For the uninitiated, here are some FAQ’s, answered :

GENERAL

Q: What are Additive Pens?

A: This is a hobby. A project to make 3D printed fountain pens.

Q: What is the difference between Additive Pens and other 3D printed pens?

A: Additive Pens are 3D printed because they cannot be made using any other method. Almost all other 3D printed pens are typically 3D printed for the sake of 3D printing. They can be made with other techniques like injection moulding, CNC machining or sculpting by hand.

Q: Can you send me 3D files, so I can print a pen myself?

A: Unfortunately not. There are many proprietary processes developed for Additive Pens, 3D printing itself is just a part of manufacturing process

Q: Do you take commissions?

A: Potentially, please reach out with details using the contact form in our website.

TECHNICAL – PEN

Q: What kind of nibs are available?

A: I use JoWo nibs and feeds most of the time.

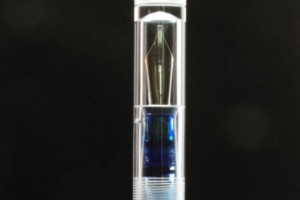

Q: How do you fill Additive Pens?

A: All designs, unless otherwise noted, are so called eyedroppers. This means that you need an ink bottle and a syringe.

Q: Is barrel staining an issue?

A: I performed tests with various inks and discoloration is there. This becomes unnoticeable when the pen is filled with any ink.

TECHNICAL – MANUFACTURING

Q: How are Additive Pens made?

A: All pens are printed using Form printer from Formlabs with original Formlabs Clear Resin. Parts are hand polished unless otherwise specified and threads are cut, not printed.

Q: Are there any extra considerations for use?

A: Additive Pens are UV light sensitive, therefore are not to be left in direct sunlight. They are also more prone to cracking than modern injection moulded pens, but not more than a typical vintage fountain pen. They should not be carried in pants’ pockets.

For More Information:

Editor’s Note:

Additive Pens are available in India. You can check out the PenWorld.Com website for details.

a 3D printed pen? sounds awesome. when will they be available here in India? any idea about the pricing?